Salian Container

Buy and sell ISO Tank and Flexitank

Salian Container is a long-established company in Iran that deals in the sale and purchase of containers, especially the purchase and sale of new and second-hand (used) isotank and flexitank containers. You can contact this company to buy a new or second-hand isotank and flexitank container, cheap and high-quality, and use the many years of experience and technical advice of its experts. As you know, buying a tanker container (isotank / flexitank) is an important and highly specialized task!

- Buy ISO Tank

- Price of ISO Tank

- Buy Flexitank

- Price of Flexitank

Cash on Delivery

By paying the round-trip transportation cost as a prepayment, you can receive the container at your location and pay the container price upon delivery.

Lift off / lift on /strip / warehousing

With the most Free Time of region (The first 60 days are free)

Up to date equipment for transportation and handeling

IRAN (Tehran, Isfahan, Mashhad) – Dubai (Jebel Ali, Al Hamriya) – China (Shanghai, Dalian, Xi’an)

Cooperation in unloading, loading, and shipping containers along with cargo from China to Iran, from Iran to China, and to other ports around the world

Get a free consultation

Did you know that 90% of the world’s commercial goods are moved by containers? Therefore, it is very important that you choose a container that is both cheap and high quality. Contact us to buy and inquire about the price of new and second-hand containers.

Are the dimensions and load capacity of the container exactly as stated on this page?

The philosophy of making containers has been to integrate means to transport goods; But it should be kept in mind that due to the existence of various manufacturers, the dimensions of the container may differ by a few centimeters, which of course is not very important. The maximum weight (tonnage) of loading the container is also determined based on the CSC Plate of the container. But in addition to the tonnage of the container, the ship and the line in which the container is to be transported should be considered. For example, when shipping to Canada, there are container tonnage restrictions, which will result in fines.

Why should we choose "Salian Container"?

Choose container types

We can provide any type of container for you.

New and used container

No matter if you want new or used container.

Cheap and high quality

Contact us to inquire about containers.

Several privet areas in Iran

Tehran, Isfahan, Mashhad and Bandar Abbas

On this page, we want to talk about isotank and flexitank containers, which are usually used to transport powders, liquids and gases in bulk. Also, we want to check the technical specifications and standard types of Isotank and Flexitank containers.

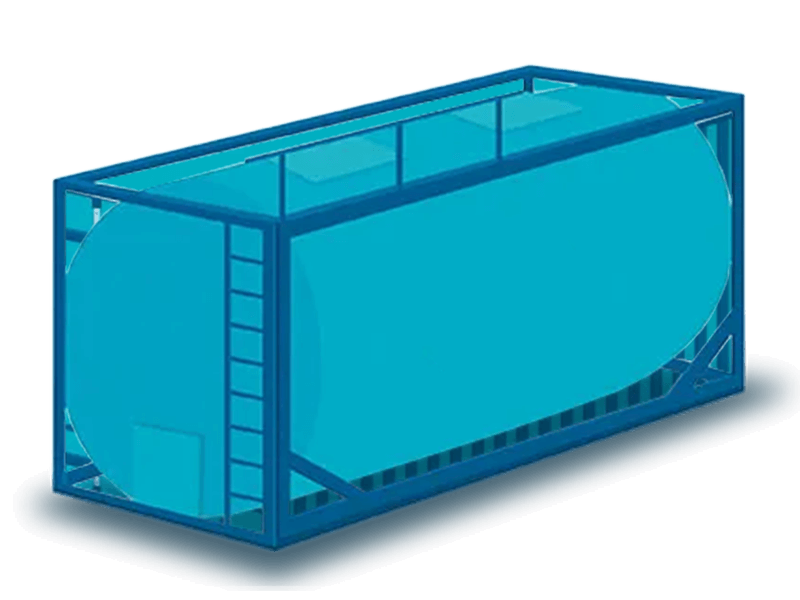

ISO Tank Container

ISO Tank Containers are tanks and tankers based on ISO global standards for the bulk transportation of powders, gases and hazardous liquids (such as flammable substances, agricultural pesticides, etc.) or non-hazardous (such as fruit juice, milk, etc.) are produced and used. These are the most common tanker containers; That is, they are in the form of a stainless steel cylinder placed in a cubic frame. These tanks are made of stainless steel and insulation and a protective layer of aluminum or polyurethane.

In other words, an iso tank is a container from which there is no penetration or leakage of all kinds of fluids. The name of Iso tank containers is taken from the International Organization for Standardization (ISO) and these tanks must be built according to these industrial and commercial standards. That is, for example, its size, durability and strength must be in such a way that it complies with ISO standards.

In fact, the iso tank structure is a combination of a container and a tank; So that the external dimensions are usually like a 20 feet by 40 feet container. In general, Iso tank containers have external dimensions of 20 feet and 40 feet, and their capacity is usually between 14,000 and 27,000 liters. Of course, a 20-foot iso tank container can carry liquids about 66% to 68% more than a normal 20-foot container filled with a drum.

What materials can be transported with an isotank?

There is a common belief that isotanks are only used to transport hazardous materials; While this is not the case and they are also used to carry non-hazardous materials. In general, the materials that are transported with isotank containers have a wide range; But some of them can be stated as follows:

- All kinds of powders and all kinds of gases

- Food; Such as water, juice, milk and dairy products, drinks, edible oils, etc.

- Car oils, petroleum products and products of petrochemical industries

- acids and chemicals; Such as poisons, hydrogen peroxide, sulfuric acid, etc.

- industrial chemicals; such as liquid detergents, lubricants, fertilizers, liquid latex, paints, etc.

- fuels; such as gasoline, diesel and compressed natural gas (CNG)

One thing that should be noted is that according to the liquid and gas that is to be transported, the type of isotank container must also be different; For example, a container used for food cannot be used to transport other materials.

Do they transport solid materials with ISO Tank?

Sometimes solid materials are turned into liquid with high heat and pumped into the tank. This material is solid throughout and is re-melted at the destination with hot steam. This process reduces the life of the Isotank container.

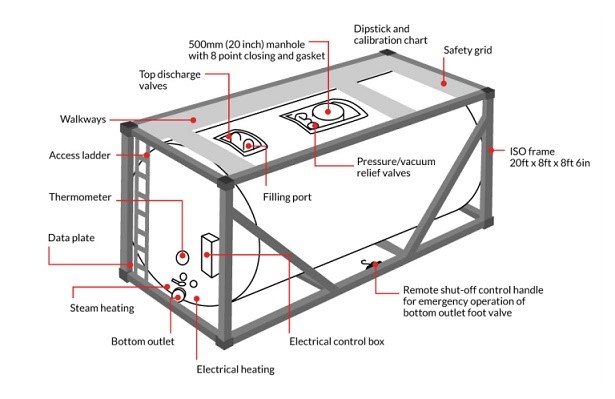

What are the components of an ISO Tank container?

ISO Tank container, like any other type of container, consists of components that can be named as follows; But due to the sensitivity of the cargo that this container carries, its components are more than other containers:

- Cylinder-shaped tank (made of different alloys depending on its application)

- Steel frame (holds the cylinder and is usually made of stainless steel)

- Upper hatch (for visiting and entering the container)

- Valves (top inlet valve, bottom or top drain valve, PV safety valve)

- Ladders and overhead walkways (for easier access when loading and unloading)

- Thermometer and pressure gauge (to display the temperature and pressure inside the tank)

- Thermal and electrical equipment (to control the temperature and pressure inside the reactor and change them)

- Specification board (tanker information / CSC license plate)

Types of ISO Tanks, their use and capacity

In terms of dimensions and capacity, isotanks are divided into the following two categories:

- 20 feet (14,000 liters)

- 40 feet (27,000 liters)

Of course, it should be noted that sometimes it is not possible to load with maximum capacity due to gas production and volume increase during isotank movement. For this reason, before loading, detailed checks of the MSDS of the product should be done so that the loading is done based on the opinion of the experts, in order to avoid spillage and damage to the isotank.

In another classification known as T-coding, isotanks can be divided into the following based on the minimum pressure they can withstand and the thickness of the tank wall:

- T1 and T2 tank, which has a wall thickness of 6 mm and can withstand a minimum pressure of 1.5 bar, and is used for carrying light liquids.

- The T3 to T5 tank, which has a wall thickness of 6 mm and can withstand a minimum pressure of 2.65 bar, is used to carry non-dangerous aromatic and odorless oils.

- The T6 to T10 tank, which has a wall thickness of 6 mm and can withstand a minimum pressure of 4 bar, is used for transporting non-hazardous chemicals.

- Tank T11 to T14, which has a wall thickness of 6 mm and withstands a minimum pressure of 6 bar, and is used for transporting dangerous chemicals and acid.

- The T15 to T22 tank, which has a wall thickness of 6, 8, and 10 mm and can withstand a minimum pressure of 10 bar, is used for carrying LPG gas and ammonia gas.

- Tank T50 to T70, which must bear different pressures according to the gas pressure and the type of gas inside the tank.

But in general, Isotank containers can be named as follows:

(1) BAFFLE TANKS

This type of isotanks is used for products with high gravity, in which the maximum amount of fullness of the tanker should be 80%. In this container, there are a series of perforated plates that allow the movement of liquid between the plates to control the movement of liquid inside the tank.

(2) LINED TANKS

These isotanks are used for very pure or corrosive liquids. These isotank containers can have layers of Teflon, rubber, phenolic resin, etc., depending on the liquid they carry.

(3) HEATED TANKS

Sometimes liquids are transported in isotanks that need to be kept warm during transportation or heated at the destination; Therefore, this type of isotanks should be used. These containers have heating systems with steam or hot water or electricity. Of course, these heating systems must be very precise; Because some materials (such as food items or medicines) may be irreparably damaged in the event of thermal shocks.

(4) GAS TANKS

These isotanks are used to transport fuels (gasoline, diesel, etc.) that have a layer of zinc metal in the inner part and stainless steel in the body.

(5) REFRIGERATED TANKS

These isotanks are used to transport materials that need cold; Such as transporting pharmaceuticals, fruit juices, milk, etc., this cold transfer is done by the cooling agent or synthetic oils around the cooling coils.

In the picture below, you can see a refrigerated isotank container, where the cooling parts and the coolant transfer pipes can be seen.

What are the advantages of transporting materials with ISO Tank containers?

Carrying materials with isotank containers has many advantages that we want to review in this section. But in general, know that in today’s transportation system, liquids are transported in three ways:

- Shipping by barrel and shipping by container and ship

- Shipping in bulk and by tank ship

- Transportation by isotank and ship

Also, transporting gases is done in two ways:

- Shipping in bulk and by tank ship

- Transportation by ISO Tank and ship

(1) Affordability

The point is that sending bulk cargo with a tank ship is done in a large volume, and there must be special facilities for loading, unloading and storing liquid bulk cargo in ports. Therefore, the simplest and most economical way to ship liquid and gas cargo in bulk is to use an ISO Tank.

(2) Easier transportation

Another advantage of isotanks is that they can be used in rail, road and sea transportation easily and without the need for any complicated equipment. As a result, it is possible to reduce up to 30% of handling costs by using isotanks. Of course, sea transportation is less risky than road and rail transportation.

(3) More load capacity

Another advantage of Isotank containers is their greater capacity compared to containers that are filled with barrels. For example, the capacity of a 20-foot isotank container is about 66% greater than that of a regular 20-foot container filled with barrels.

(4) High reliability and safety

As mentioned, most isotanks have a multi-layer stainless steel body and have high resistance to different temperatures, pressures, and shocks. As a result, they have high safety for transporting materials. Also, they can accommodate temperature sensitive loads.

Also, the possibility of spillage and leakage in this container is very low due to strict adherence to standards. Therefore, it can be said that it is environmentally friendly. Isotanks can withstand harsh weather conditions.

(5) Easy storage

Due to the strict standards in the production of isotanks, the possibility of leakage in them is very low. Also, due to the metal frame around the tank, they can be placed on top of each other to occupy less space. These two features make them the best containers for storing liquid and gas materials.

Is it possible to wash the inside of the ISO Tank container?

The most concern of ISO Tank customers is that the traces left from the previous load will affect their load and lower the quality of the goods. For this reason, ISO Tanks must be washed. Of course, after washing, you should use the same material as the previous one. For example, food should never be transported in containers that have even once contained chemicals.

There are companies that wash ISO Tanks. with processes such as washing with high pressure hot and cold water and detergents, aeration inside the tank, steam washing inside the tank

FlexiTank Container

As mentioned, isotanks have a multi-layered steel body that is placed in a solid metal frame; But flexitank containers are not like that.

FlexiTanks Containers are flexible polyethylene or PVC (PVC) tanks that are placed inside a container, usually 20 feet or larger, and filled with liquid to transport it to its destination. Therefore, the flexitank can be considered as a collapsible and flexible bag that is used to transport non-hazardous liquids and can hold up to 24,000 liters of liquid cargo.

Flexi tanks weigh less than isotanks (at least by one ton). Also, the most important feature of the flexitank container is that it costs less than the isotank and is more affordable.

The flexi tank is made of one to several layers of polyethylene or PVC (PVC), whose outer cover is made of polypropylene.

Among the advantages and important features of flexi tanks, the following items can be mentioned, which have attracted a lot of attention for merchants and manufacturers:

- to be economical

- Optimal carrying and storage capacity

- Maintain product quality

- Fast loading and unloading

Flexi tanks can be classified according to the number of unloading and loading valves as follows:

- Single-valve flexi tank: loading and unloading valve from above

- Single-valve flexi tank: loading and unloading valve from the bottom

- Flexi tank with two valves: one loading valve from the top and one draining valve from the bottom

What materials can be transported with a Flexitank?

All materials that can be transported with isotanks can also be transported with flexi tanks; Only with the difference that flexi tanks are not used to transport gas. Also, to transport or store fuels, a type of flexi tank is used, which is multi-layered and much more secure. Therefore, all of the following materials can be transported with flexi tanks:

- All kinds of powders

- Food; Such as water, juice, milk and dairy products, drinks, edible oils, etc.

- Car oils, petroleum products and products of petrochemical industries

- acids and chemicals; Such as poisons, hydrogen peroxide, sulfuric acid, etc.

- industrial chemicals; such as liquid detergents, lubricants, fertilizers, liquid latex, paints, etc.

- fuels; such as gasoline, diesel and compressed natural gas (CNG)

Also, flexitanks can be stacked and used as a warehouse or temporary storage of liquid or powder materials.

The price of new or used ISO Tank and Flexitank

Like any other product, a single price cannot be announced for the purchase of Isotank or Flexitank containers; Because the conditions of each container are different and there are various parameters that affect the price of an Isotank or Flexitank container; Such as production brand, tank capacity, body type, new use, year of production, container equipment, etc.

Another parameter that affects the price of an isotank or flexitank container is the currency price; Because usually these containers are imported and are bought and sold at the price of dollars or other world currencies. The price of isotanks is usually between 10,000 and 50,000 dollars in global markets.

Therefore, you should purchase containers based on your budget; But if you are looking for a cheaper purchase, you can also use a used isotank or flexitank container.

We suggest that you contact Salian Container Company and get guidance from the experts there to buy.

What is ISO Tank Container?

Cylindrical tanks made of stainless steel and based on global ISO standards, which are placed in a cubic frame and are used for the bulk transportation of powders, gases and hazardous liquids (such as flammable substances, agricultural pesticides, etc.) or non-hazardous (such as water) fruit, milk, etc.) are produced and used.

What materials can be transported with an ISO Tank container?

Isotanks are used to transport powders, liquids and gases; Whether they are hazardous or non-hazardous materials.

What is FlexiTank Container?

Flexible tanks are made of polyethylene or PVC (PVC) that are placed inside a container, usually 20 feet or larger, and filled with liquid to transport it to its destination.

What materials can be transported with a flexi tank container?

All materials that can be transported with isotanks can also be transported with flexi tanks; Only with the difference that flexi tanks are not used to carry gas.

Hi.

Interested in buying ISO Tank Used or New. T11.

Please quote 6 Tanks

Hello. Please Call this number Phone For Better Guidance: +989170920030

Hello! We are interested in purchasing ISO tanks. Kindly check your email.

Hello! Thank you for your interest in ISO tanks. We have checked our email and will get back to you shortly with the details.